Although reverse logistics has been around for decades, it gained more traction with the sudden boom in e-commerce. More than ever before, consumers expect easy to follow return policies, which urges companies to have well-functioning reverse logistics in place.

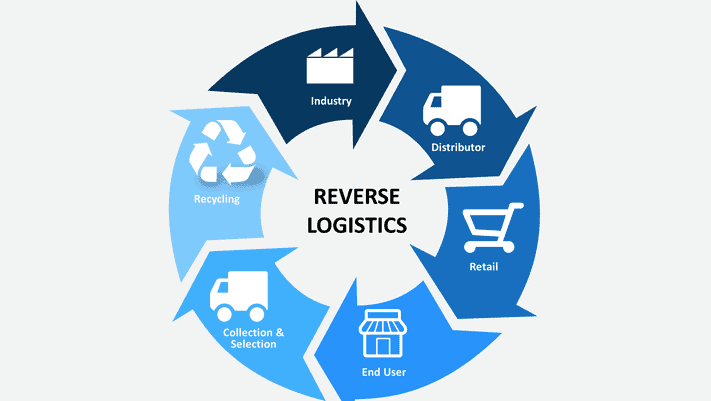

If you are wondering what exactly reverse logistics is, it is the exact opposite of the supply chain. In definition, it is the process of moving goods from their usual destinations for capturing value or for proper disposition.

In simpler terms, reverse logistics refers to the activities related to the return of products or materials. For example, in retail, when a consumer returns a product, it reaches the seller or manufacturer by the process of reverse logistics, after which the product is refurbished or remanufactured.

Products that are returned can also be resold or permanently disposed of. Another reason why reverse logistics is critical is that products are often replaced with newer versions. For example, clothes that belong to a previous season’s collection will be rarely bought by customers.

To get rid of such clothes and make space for new collections, stores will have to return goods to warehouses, which is made possible by reverse logistics. To be more precise, any process or handling of goods that occur after the initial sales involves reverse logistics.

As the reverse supply chain is an unavoidable part of manufacturing, or let alone any business, not handling it with an effective reverse logistics process can have a negative impact on a company’s profitability. Here are some of the notable benefits of reverse logistics for you to consider.

Benefits of Reverse Logistics

1. It Increases Asset Utilization

Almost every business strives to do more with less. And that’s precisely what reverse logistics can help you achieve. With the help of a well-thought reverse logistics process, companies can extend their product’s life by repairing and recycling, thus reducing any forms of wastages.

This also means that the time, costs, and human resources invested in the original supply chain aren’t lost. By quickly acquiring returned goods, companies can extract more value from it, by repairing or recycling.

Another way reverse logistics helps in increased asset utilization is in the case of transportation. When fleet vehicles visit distribution centers for delivery, they can pick up returnable materials and bring them back to the production centers, leaving no room for underutilization of resources.

If not for reverse logistics, trucks will have to return empty and make double trips when there is a need for collecting returnable materials.

2. It Enhances ROI and Eliminates Unwanted Costs

When a consumer returns a product, the costs associated with it are technically a loss for the company, until it is repaired, resold, or recycled.

Without a proper reverse logistics process in place, return processes will take forever to complete – meaning more of a company’s resources will be locked up. Thanks to reverse logistics, such situations are eliminated.

It also helps companies to quickly acquire returnable materials and utilize them before they expire. For example, if a lawnmower fails to work, manufacturers must speedily return it for repair, so that it can be resold before the winter season starts.

Another way to reduce costs associated is by effectively managing your fleet vehicles. And that process is made more streamlined with fleet telematics. It enables access to real-time data, which in turn improves efficiency, decreases accidents, mishaps, and errors.

3. Customers Are Happier

Customers expect no-hassle returns when they shop, especially when they do on online stores. This means organizations must be capable of managing returns without any bottlenecks in the system – hence reverse logistics.

If you can replace or repair goods without any holdup, customers will be more satisfied and will be tempted to do more business with you. This can also shape and improve your customer list, as many consumers still rely on word of mouth for purchase decisions.

Also, a happy customer is a loyal customer. If you fail to live up to customers’ expectations, they are more likely to stay away from your products and opt for your competitors instead.

4. It Reduces the Environmental Impact

Reverse logistics can help you determine quick ways to reuse, recycle, or resell goods that may otherwise be dumped in a landfill. This will not only reduce manufacturing expenses but will also help in enhancing your company’s reputation, as you are socially and environmentally responsible.

A well-defined reverse logistics process will also eliminate the need for avoidable transportation. This means your fleet vehicles will travel less to do more. Furthermore, integrating reverse logistics to the supply chain will help you decide whether a product can be repaired locally, without the need for long haul shipments.

But if you are functioning in multiple states, your fleet vehicles will have to make numerous inter-state trips for smooth functioning. For example, your warehouse may be situated in Ohio but will have stores in Michigan.

This means you will have to track the miles traveled, the HOS of your drivers, and the amount of fuel filled by your fleet vehicles, from each state, to account for the IFTA tax.

5. It Shapes a Better Corporate Image

One of the most noticeable benefits of utilizing reverse logistics is the boost it can give to your company’s image. A company that invests in eco-friendly and customer-friendly practices will always be looked up to.

By adopting an effective reverse logistics strategy, your company is being more responsible and accountable for its products and services. It is almost like reassuring your customers that they can count on you, no matter what.

In Conclusion

Reverse logistics offers an effective way to recycle, refurbish, or dispose of your products. To be precise, without reverse logistics, a supply chain is incomplete as not all goods can be sold and forgotten without dealing with returns.

With reverse logistics, you are priming your organization to eliminate any forms of revenue losses that reverse supply chain can cause. If you are yet to have a well-defined reverse logistics system in place, you are missing out a lot.