How much time and effort does the Stock Inventory Software save you? For creating work orders, bills of materials, and other production-related documents in the manufacturing industry, stock inventory software is a must-have.

So, what is stock management software, exactly? To put it simply, the software system tracks inventory levels, sales, and delivery as well as orders. To avoid overstock and outages, the organization typically employs this software. Inventory management software can also be characterized as a tool that organizes data before it is stored on paper or in a spreadsheet.

What are the benefits of using stock management software free? The answer must have a lot to do with the software’s goal and features, which I’ll examine in more detail in the following paragraphs. So please don’t go out and see how easy it is to arrange your company’s data using the software.

[lwptoc]

The Purpose of Stock Inventory Software

Inventory software use by most businesses to reduce the amount of inventory on hand. These products and parts may track as they move from the vendor to a warehouse, then to a customer or a retail store, all using this software.

There are some purposes of using stock inventory software that are:

- Keep the balance between too much & too little inventory.

- Receiving goods into a warehouse of another place.

- Tracking inventory once transported from one location to another location.

- Reducing product obsolescence & spoilage.

- Picking, packing & shipping the goods from the warehouse.

- Recording track of levels of the inventory & product sales.

- Prevent missing out on sales because there might be some out-of-stock situations.

The Features of Stock Inventory Software

Some of the essential elements of stock inventory software are the components that work together to make it possible for numerous companies or organizations’ systems to manage their inventory. These features include the ability to track and reorder items, inventory optimization, and product identification.

Here are the details of each feature of inventory management:

Asset Tracking

Stock inventory software’s asset tracking feature is critical due to the software’s involvement in tracking products at a warehouse or store using barcodes or other tracking methods like serial numbers.

Radio-frequency identification (RFID) and wireless tracking technology are frequently used in commercial software in addition to barcodes and serial numbers. Because stock inventory software keeps track of its assets, it is deemed crucial.

Reorder Point

Using the reorder point feature, a company’s inventory system management can program to alert managers when to place new orders for specific products. As a result of this feature, the organization can maintain enough product inventories. Thus, the inventory will be able to meet the required level.

Service Management

To provide cleaning materials to customers, the organization must focus on providing services rather than selling products. When it comes to keeping track of the costs of providing the service, the corporation employs software. Use this feature to put a price on each service to clear the overall cost.

Inventory Optimization

Another software component is inventory optimization, which uses a wholly automated demand forecasting and inventory optimization system to achieve the essential inventory optimization criteria.

Order amount specifies the number of units that must be reordered in light of the reorder point, stock order, and inventory on hand for inventory optimization.

After that comes lead demand, which is the number of units to be sold during the lead time, stock over, which is the number of days left before a stock-out occurs if no new orders are received, and forecast accuracy, which are all factors in inventory optimization.

Product Identification

This software for inventory management also includes product information as an additional function. Barcodes are used in this instance to feed product and order data into the software and provide information about the product. In addition, the software makes use of a barcode reader to decode the barcode. As a result, we can gather data on the products featured.

Radio-frequency identification tags and wireless technologies can also read the product information. Smartphones can scan QR codes or NFC tags on inventory items. It is possible to track inventories using barcode scanning without the need for expensive barcode scanning technology in this way.

3 Best Free and Open Source Inventory Management Software

I’ve gathered the three top open source and free stocking software for you to use as examples. Odoo, Square for Retail, and Zoho Inventory are the three most popular retail management systems.

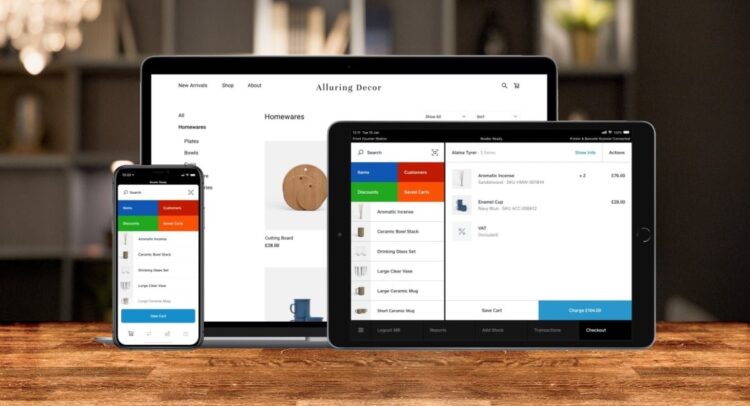

Square For Retail

Square For Retails is the following example of stock inventory software. With this program, you can run your business online and offline using cloud-based retail management and a point of sale system. The website builder, inventory management, check out and payment administration, reporting, and order management are the most critical elements of this software.

Square’s free plan includes inventory management functions for stock counting and tracking. Low stock alerts are included in the free edition and warn users when inventory levels fall below the critical order volume. Inventory restocking will begin before stock outages harm routine operations.

Square offers a variety of ways to reach out to customers, including phone, email, live chat, a knowledge base, and social media.

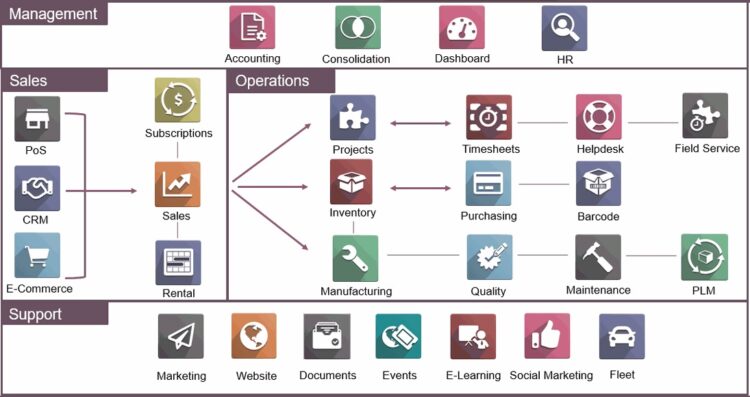

Odoo

Managing inventory is a complex task, and only warehouse or operations managers can do it. Each product’s units, item numbers, and locations are all recorded in this inventory management method. As a result, clients’ orders will be filled to their satisfaction because of the increased inventory on hand.

If you’re looking for an open-source ERP solution that can handle everything from CRM to POS to supply chain to inventory to cost tracking, then Odoo is for you.

Tracking inventory products’ delivery orders, requests, backorders, and other delivery-related activities are also possible with Odoo. Odoo’s shipping module includes FedEx, UPS, DHL, and local post offices, making the shipping process efficient and straightforward. Additionally, the module can scan barcodes via Wi-Fi, Bluetooth, and USB connections. The module’s interface with the ERP ecosystem is clear. When you sell a product, you don’t have to update your inventory and financial records manually. Additionally, Odoo provides customer assistance via site and telephone.

Zoho Inventory

It is likely the best choice for inventory management in the cloud. Zoho Inventory’s many functions include inventory management, warehouse management, order management, and multichannel sales capabilities.

The free version of Zoho Inventory allows two users to handle inventory orders, track shipments, and monitor online and offline warehouse activities. In addition, the ability to handle purchases made through an e-Commerce platform is provided by this.

FAQs, forums, email, a self-service knowledge base, and phone assistance are all alternatives for customer care.

There are 25 orders for online and offline purchases in the free Zoho inventory plan, while the subscription plans start at $49 per organization per month.

Final Words

To sum it up, stock inventory software creates to simplify your data management, particularly stock inventories. In addition, new functions are being introduced to the software to make inventory management in the company system easier.

ALSO SEE: Uninstall Unwanted Software with IObit Uninstaller

In addition, I’ve included three real-world inventory management system examples in this post. The free plans allow you to evaluate the software and decide if you need it for your business or organization before investing in a paying version.